Demystifying the Mystique: Is Masking Tape Truly Double-Sided?

In the DIY space, masking tape is a multipurpose and versatile tool used for diverse applications. But, one question that comes to every mind: Is masking tape double-sided? This article will unravel the truth of masking tape, its functionalities, and its applications.

Table of Contents

Basics of Masking Tape

Masking Tape is an adhesive tape known as the painter’s tape. It is easy to tear, has adhesive capabilities, and can be removed without unwanted sticky residue. It consists of two layers: A thin saturated crepe paper that one can tear easily, and the other one is sticky adhesive. The adhesive can be solvent-free, hot melt, or acrylic-based. Painters, DIY enthusiasts, and craftsmen use it to protect surfaces and create clean lines.

Single-Sided Nature of Traditional Masking Tape

In its original form, traditional masking tape is not double-sided. It is a tape whose primary purpose is to cohere to surfaces on one side, which acts as a shield for various objects. The sticky side adheres to surfaces, while the other side is usually left alone, allowing easy removal with minimal damage. It encourages the painters to use it as their daily tool, as it protects the wall and requires minimum strength to tear it away.

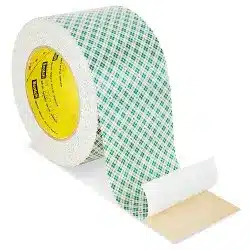

Specialty Double-Sided Masking Tape

While standard masking tape is always single-sided, some are manufactured with adhesives on both sides. Double-sided masking tape makes two surfaces stick together or where a stronger bond is required. The most crucial part is that the adhesive is not visible on the surfaces, which makes it practical. It allows the user to make neater-looking projects and better craftsmanship. We can apply it on the front and the back.

Applications of Masking Tape

1. Crafting and Scrapbooking

Masking tape is mostly used by craftsmen and DIY enthusiasts. It is also very effective in scrapbooking. Crafters use it to draw boundaries and straight lines on the walls, as it does not harm the walls. Scrapbooking is another domain that extensively utilizes the wonders of masking tapes. Printed and colourful masking tapes are more practical for scrapbooking and provide aesthetic value and beautification.

2. Mounting and Attaching

It is where the double-sided masking tapes shine the most. When we attach or mount something on the surface. We need adhesives on both sides. Double-sided masking tape provides this with little to no waste. They are easy to use, apply and tear. The strength of the masking type highly depends on the adhesive used in it. The composition and chemicals in the adhesive determine its strength. 3M 201+ General Masking Tape is one example of it. Users use this to bundle things like cords, hoses, and pipes.

3. Sealing and Bonding

Some specially curated double-sided masking tapes have a high-strength adhesive that helps in sealing packages, objects, and heavy-duty applications. The adhesive used in these tapes is more robust. Some special masking tapes, such as 3M 401+ / 233+ High-Performance Masking Tape can endure temperatures up to 2500 F.

4. Automotive Industry

In the automotive industry, masking tapes are crucial for covering areas such as trim, windows, or any sensitive parts of the vehicle. They are also significant in body repair, as they can hold onto the surfaces without damage. No Edge Blending Tape is one of the few tapes for this job.

5. Painting Industry

Masking tapes are extensively used in painting projects to create clean and straight lines on the walls, between different painted surfaces. It helps in attaining precise and accurate results and also prevents paint bleeding. It can be applied to protect surfaces from scratches, dents, or other damage during construction and renovation.

Choosing the Right Masking Tape for Your Project

When selecting masking tape for your project, it’s essential to consider the specific requirements. If you’re looking for an easily removable option for painting or crafting, traditional single-sided masking tape is sufficient. However, if you require a stronger bond or need to attach items permanently, opting for double-sided masking tape is the way to go.

Tips for Using Double-Sided Masking Tape Effectively

1. Surface Preparation

Make sure that the surfaces on which you will use the masking tape are clean, dry, and free of dust. Any form of moisture and dust affects the quality of the adhesive. To increase the tape’s adhesion and longevity, make proper surface preparations. If you do not adhere to these instructions, you might face a loss.

2. Weight Considerations

Plan everything before buying a masking tape. Different double-sided masking tapes have varying levels of adhesive composition, which affects their weight capacities. If you want to join the bundles of wires, 3M 201+ General Masking Tape is one example. You can go above the notch and buy 3M 401+ / 233+ High-Performance Masking Tape.

3. Temperature Sensitivity

Just like the adhesion, different masking tapes have various heat resistance. Some tapes can endure 1200 F of temperature while others can endure up to 2400 F. These variations can sabotage your decision. But if you plan it before you buy it, it can save you a handful of money.

The Verdict: Masking Tape – Single or Double-Sided?

In short, a typical masking tape is not double-sided. However, you can find diverse specialty masking tapes tailor-made for specific applications. If you want to buy a masking tape with high heat resistance or with high adhesive strength, you can get it all. Whether you do crafty stuff, house renovation, or bond and seal some objects together, you most likely want to have a masking tape in your arsenal.

The Internet is a pool of information. You can easily find the most suitable masking tape that fits your need. So, the next time you want to buy masking tape, consider the unique demands of your project and choose the appropriate tape, single or double-sided. It makes your creative endeavours or practical tasks smooth. The world of masking tapes can be intimidating for beginners, but there is no need to worry. You just need to research and make the best decision possible.